SAFETY FIRST: Protective gloves and eyewear are recommended at this point.

Note: These instructions are very general, and you should have a service manual for your particular vehicle to get a better understanding of your particular setup and have factory recommended torque levels and specifications on hand.

Check out the Additional Service Information Resources for more information on finding service information for your specific vehicle.

Prep

Thoroughly clean the vehicle to make the job easier and prevent contamination of the new components during installation.

Get your steering bearing kit from ALL BALLS RACING.

Remove the contents of your ALL BALLS RACING steering bearing rebuild kit. Layout the components in an organized manner for easy installation. Note: wait to do this until the old parts are removed and you are ready to begin installing the new components.

Removal

Remove the following components:

- Front Wheel

- Front Fender

- Front Forks

- Handlebars

Remove the steering stem nut.

Lift the upper fork clamp off the steering stem.

Loosen and remove the adjusting nut.

Make sure to support the lower triple clamp with your free hand, as it can fall out with the nut removed.

Remove the bearing cover.

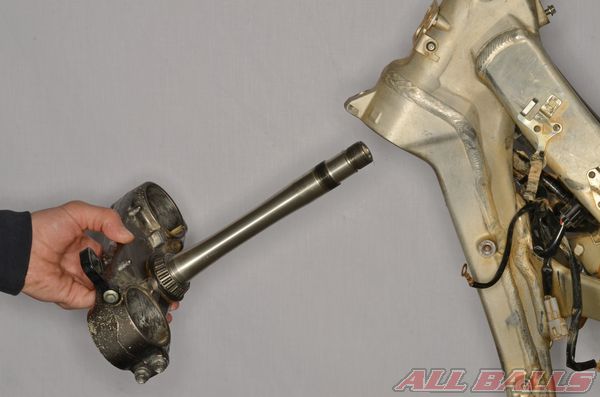

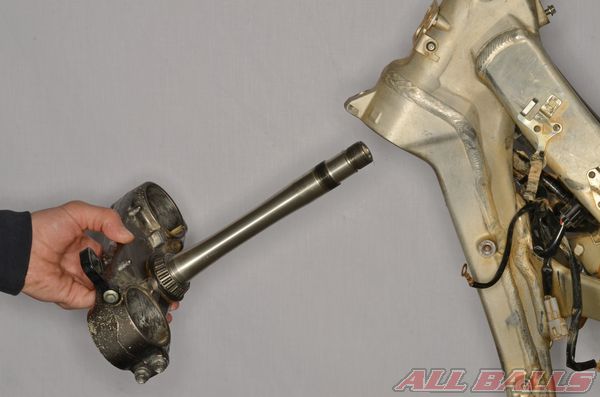

Remove the lower fprl clamp and steering stem from the steering head.

Lift out the upper bearing.

The lower bearing rides on the steering stem.

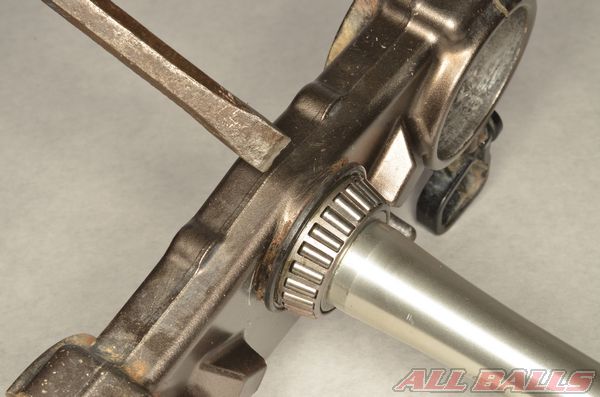

Remove the lower stem bearing by tapping a chisel between the bearing and the triple clamp. Work your way around until the bearing pops free.

Remove the lower bearing and dust seal.

Clean away all of the old grease, grime, and rust from the bottom of the steering stem.

The bearing races are in the steering head of the frame. There are two races – one for the upper bearing and one for the lower.

Remove the steering bearing races with a steering bearing race remover tool.

If a steering bearing remover tool is not available, remove the bearing races by knocking them out with a drift and hammer.

Have the drift set against the lip of the race, and work around the race evenly to drive it out.

Remove the upper and lower bearing races.

Clean away all of the old grease, grime, and rust from the bearing bores. Inspect the condition of the steering head in the frame. Remove any burrs that may inhibit the installation of the new bearing races.

Installation

Be sure to install the upper and lower bearings and races to their proper positions.

Make sure the steering stem is clean and in good condition to accept the new bearing and dust seal. Remove any burrs from the stem that might prevent smooth bearing installation.

Lubricate the dust seal lips with grease.

Apply a light coat of grease to the inside diameter of the lower bearing to aid installation.

Fit the new dust seal and lower bearing onto the steering stem.

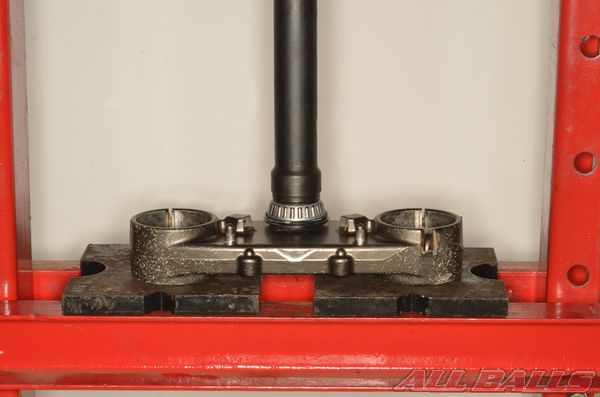

Use a press with a steering stem bearing installer tool to install the lower bearing onto the steering stem.

Make sure the bearing installer tool or pipe, only makes contact with the inner race of the bearing. Pressing on the cage of the bearing will distort it and may cause binding in your steering.

Install the new bearing races into the steering head of the frame.

Use an appropriate bearing race installation tool to install the races into the steering head of the frame. Makes sure the bearing races go in straight. Do not apply pressure to the tapered portion of the races to prevent damage.

A tool can easily be made with a piece of threaded bar stock some nuts that fit it and some washers that have a slightly smaller outside diameter as the races that you are installing.

After the bearings are pulled in hit both ends of the threaded rod with a hammer to fully seat the bearings.

A suitable bearing race driver may also be used to install the races into the steering head. Make sure the driver fits the race correctly and take care to drive race in straight.

Lubricate the bearings with grease.

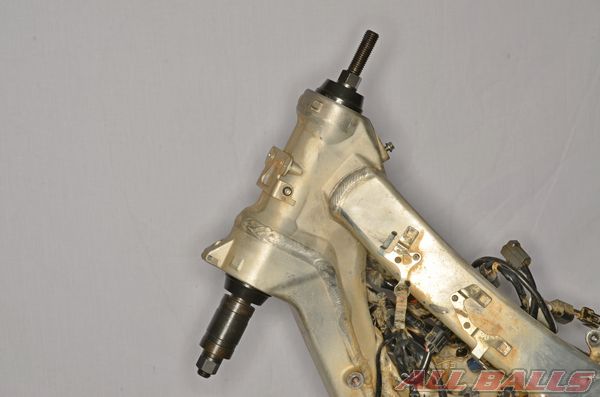

Install the upper bearing into its race.

Fit the steering stem into the steering head of the frame.

Install the upper dust seal.

Thread on the adjusting nut.

Tighten the adjusting nut with a pin spanner. Follow any specific adjusting nut instructions in the service manual

General Adjusting Nut Information – Tighten the adjusting nut securely. Turn the steering stem lock-to-lock several times to seat the bearings. Loosen the adjusting nut 1/4 to 1/2 half turn. Adjust the nut so the steering moves correctly. The adjusting nut should be tight enough so that any vertical movement is eliminated. However, it should not be so tight as to cause binding or require excessive force to turn.

Note: Some models have specific initial and final torque specs or tightening sequences for the adjusting nut.

Fit the upper fork clamp into place.

Install the steering head nut.

Install the forks and tighten the steering stem nut to specification.

Install the following components:

- Front Wheel

- Handlebars

- Front Fender

Make sure the steering moves smoothly without any vertical movement or needing excessive force. Adjust the steering stem adjusting nut if needed.

INSTALL ALL BALLS RACING STICKER!