SAFETY FIRST: Protective gloves and eyewear are recommended at this point.

Note: These instructions are very general, and you should have a service manual for your particular vehicle to get a better understanding of your particular setup and have factory recommended torque levels and specifications on hand.

Check out the Additional Service Information Resources for more information on finding service information for your specific vehicle.

Prep

Thoroughly clean the vehicle to make the job easier and prevent contamination of the new components during installation.

Get your shock absorber bearing rebuild kit from ALL BALLS RACING.

Note: Some shock absorber bearings are included with the linkage kit.

Remove the contents of your ALL BALLS RACING shock bearing rebuild kit.

Layout the components in an organized manner for easy installation. Note: wait to do this until the old parts are removed and you are ready to begin installing the new components.

Remove the plastic wrapper from needle bearings and push it into the inside of the bearing to retain the needles.

Removal

Support the vehicles frame and swingarm so the vehicle weight is not supported by the shock absorber. Follow any specific instructions in the vehicle’s specific service information.

Remove the shock absorber from the vehicle.

Check for swingarm, linkage, frame damage and excessive wear. Check the pivot bolts for damage and excessive wear. Replace any worn or damaged components as necessary.

Spherical Bearing

Inspect the shock absorber for damage and excessive wear.

Remove the side collars from the dust seals.

Remove the dust seals.

Check the bearing for snap rings or circlips.

Remove the circlip from its groove.

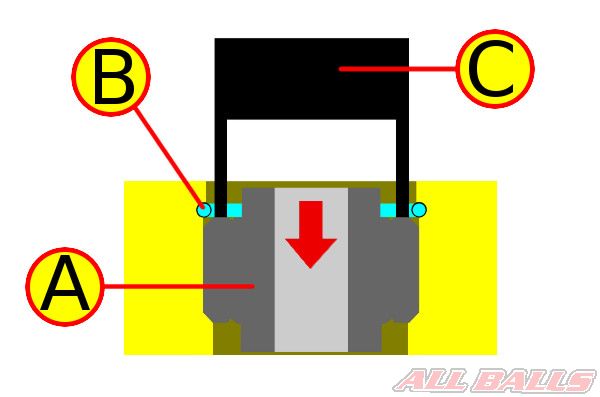

If the circlip is difficult to remove, press the spherical bearing (A) further in with an appropriately sized press collar (C) to allow more clearance to remove the circlip (B).

Press the bearing out towards the direction of the criclip.

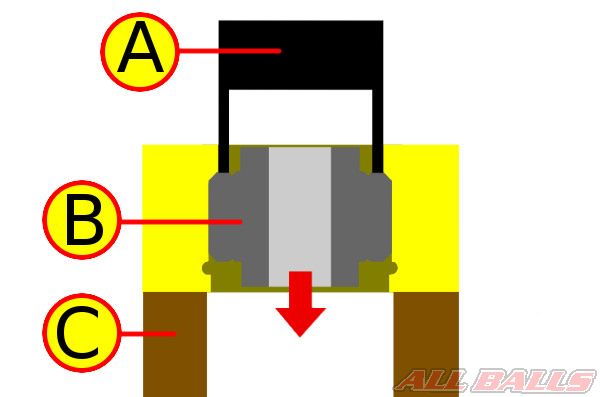

Press the bearing (B) out with an appropriately sized press collar (A). Use an appropriate support (C) to make sure the bearing has room to exit the shock absorber.

Clean away all of the old grease, grime, and rust from the bearing bore.

Inspect the bearing bore for wear and damage. Make sure the bore is free of damage or burrs that may cause the new bearing to hang during installation.

Press in the new bearing from the side with the circlip.

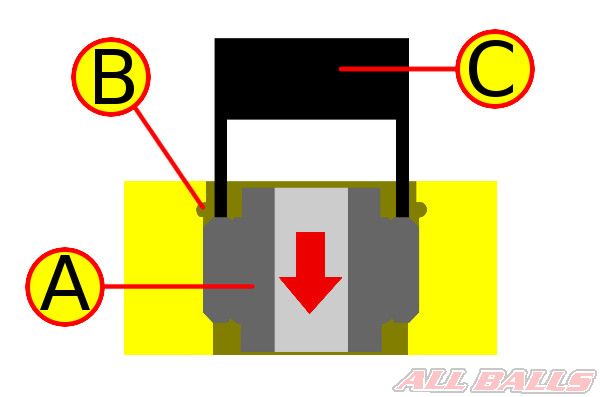

Use a suitable press collar (C) that only makes contact with the outer race of the bearing (A).The bearing should be fully seated so the circlip groove (B) is visible.

Install the circlip into the groove.

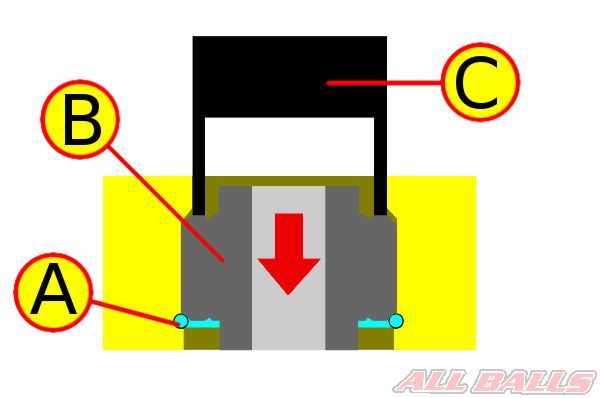

Press the bearing (B) in with a a suitable press collar (C) so that it is secure against the circlip (A).

Apply grease to the lips of the dust seals.

Install the dust seals with the markings facing out. Often the dust seals can be gently pressed in by hand. If needed use a suitable driver with the same outside diameter as the seal to press the seal into the bore.

Install the side collars into the dust seals.

Needle Bearing

Inspect the shock absorber for damage and excessive wear.

Remove the dust seals and side collars. Note the component original positions for assembly.

Remove the pivot collar.

Check the condition of the bearing. If the bearing is loose, damaged or corroded, it must be replaced.

Note the depth of the bearing so the new part can be installed to the correct position.

Press out the old bearing. Allow room for the bearing to exit the opposite side of the shock absorber.

Clean away all of the old grease and rust from the bearing bore.

Inspect the bearing bore for wear and damage. Make sure the bore is free of damage or burrs that may cause the new bearing to hang during installation.

Lubricate the bearing with grease.

Apply a light coat of grease to the outside of the outer bearing race for smooth installation.

Press in the new bearing. Use a suitable driver that is slightly smaller than the outside diameter as the bearing.

Make sure the bearing is at the proper depth in its bore. In this example of a 2010 Yamaha YZ450F, the lower bearing must sit 4 mm (0.16 in) below the outer surface of the shock.

Make sure the bearings are properly greased.

Lubricate the lips of the dust seals with grease.

Fit the side collars and dust seals together.

Install the dust seals with the markings facing out. Often the dust seals can be gently pressed in by hand. If needed use a suitable driver with the same outside diameter as the seal to to press the seal into the bore.

Position the seal as indicated in the service manual. The seals should be flush with the edge on our 2010 Yamaha YZ450F.

Lubricate the pivot collar with grease.

Insert the pivot collar into the bearing.

Install the opposite side dust seal and side collar.

Installation

Apply a light coat of grease to the shock absorber pivot bolts. Install the shock absorber and pivot bolts. Install the bolts in the correct positions.

Take care to properly support the vehicles frame and swingarm so the vehicles weight is not applied to the shock until it is fully installed.

Return the vehicle to the ground so that its weight is supported by the rear suspension, and tighten the fasteners to the correct torque specifications. Follow any specific instructions in the vehicle’s service manual.

To make your bearings last longer- avoid pressure washing around the bearing seals for extended periods of time. Pressure washers will push water right around seals causing premature rusting of the bearings.

INSTALL ALL BALLS RACING STICKER!