SAFETY FIRST: Protective gloves and eyewear are recommended at this point.

Limited Slip Differential Clutch Torque

Inspect the front differential limited slip differential (LSD) if the handlebars are hard to turn, the front gear case overheats, or the front gear case makes unusual sounds when cornering.

To test the LSD clutch torque support the vehicle with a suitable stand or jack so that both front wheels are off the ground. Remove one of the front wheels. See the Wheels and Hubs topic for more information.

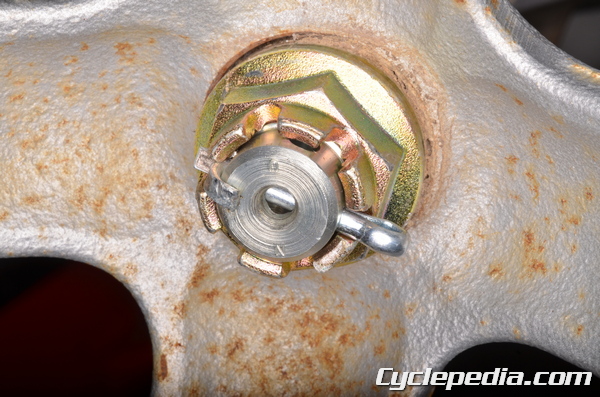

Straighten the cotter pin and remove it from the hub nut on the same side the front wheel was removed. Secure the opposite wheel to prevent it from being able to turn.

Place a 27 mm socket on a torque wrench and turn the hub nut clockwise. Record the amount of torque over 1/4 turn of the axle. Do this with the differential control lever pulled in and free.

Control Lever Is Released: 15-20 N-m (1.5-2.0 kgf-m, 11 -14 ft-lb)

Control Lever Is Pulled In: 157 N-m (16 kgf-m, 116 ft-lb) or more

If the lever torque is out of specification inspect the differential clutch pack. See below for more information.

Gears

Inspect the ring and pinion gears for signs of wear and damage. The gears must be replaced as a set. To replace the ring gear see the Differential Disassembly topic for more information. To replace the pinion gear see below.

Gear Adjustment

The ring and pinion gears must maintain correct backlash and tooth contact for performance and reliability. If the final gears are making noise the gear backlash/tooth contact may be out of specification. Check the backlash and tooth contact if any of the gears or other backlash related components are replaced.

Always check and adjust the backlash before the tooth contact.

The shims with the ring and pinion gears affect the amount of backlash and adjust the gear tooth contact. The shim/s with the pinion gear play a greater roll in setting the correct tooth contact, while the shim/s on the ring gear play a greater roll in setting the correct backlash.

Backlash

Assemble the front differential. Temporarily insert the right front axle. Position the differential so that the pinion gear is above the ring gear as if installed in the vehicle. Hold the front axle to keep the ring gear from turning.

Place a dial gauge on the pinion gear shaft and turn the pinion gear shaft back and forth. Measure the amount of backlash between the pinion and ring gears.

Bevel Gear Backlash At Pinion Gear Spline: 0.10 – 0.20 mm (0.004 – 0.008 in.)

If the backlash is out of specification the shim/s must be adjusted.

Ring Gear Right Shims for Backlash Adjustment

Thickness | Part Number

0.15 mm (0.006 in.) | 92180-1399

0.2 mm (0.008 in.) | 92180-1400

0.5 mm (0.020 in.) | 92180-1401

0.7 mm (0.028 in.) | 92180-1402

0.8 mm (0.031 in.) | 92180-1403

0.9 mm (0.035 in.) | 92180-1404

1.0 mm (0.039 in.) | 92180-1405

1.1 mm (0.043 in.) | 92180-1406

1.2 mm (0.047 in.) | 92180-1407

Ring Gear Left Shims for Backlash Adjustment

Thickness | Part Number

0.15 mm (0.006 in.) | 92180-1390

0.2 mm (0.008 in.) | 92180-1391

0.5 mm (0.020 in.) | 92180-1392

0.7 mm (0.028 in.) | 92180-1393

0.8 mm (0.031 in.) | 92180-1394

0.9 mm (0.035 in.) | 92180-1395

1.0 mm (0.039 in.) | 92180-1396

1.1 mm (0.043 in.) | 92180-1397

1.2 mm (0.047 in.) | 92180-1398

Tooth Contact

Set the backlash correctly before checking the tooth contact.

To check the gear tooth contact a special compound will be needed. The kind of compound used for checking automotive differential gears may be used. This can be found at many auto supply stores. Make sure the compound is smooth, firm, and around the consistency of tooth paste.

Thoroughly clean the teeth of the pinion and ring gears.

Apply the contact checking compound to the to 4 – 5 teeth on the pinion gear. Use a stiff bristle paint brush to apply the compound evenly. Do not use an excessive amount.

Assemble the front differential. The backlash must be set correctly at this point or you are wasting your time.

Hold a gentle drag on the ring gear while turning the pinion gear shaft. Turn the pinion gear shaft 3 – 4 turns in the forward direction and the same in the reverse/coast direction.

If the contact is far out of center the shim/s need to be changed. Change the shim/s a small amount at a time and recheck the tooth contact and backlash. Clean the checking compound from the teeth before each inspection.

Pinion Gear Shims for Tooth Contact Adjustment

Thickness | Part Number

0.15 mm (0.006 in.) | 92180-1408

0.2 mm (0.008 in.) | 92180-1409

0.5 mm (0.020 in.) | 92180-1410

0.7 mm (0.028 in.) | 92180-1411

0.8 mm (0.031 in.) | 92180-1412

0.9 mm (0.035 in.) | 92180-1413

1.0 mm (0.039 in.) | 92180-1414

1.1 mm (0.043 in.) | 92180-1415

1.2 mm (0.047 in.) | 92180-1416

Double check the gear backlash after the tooth contact has been set correctly. The backlash must remain in specification.

Bearings and Seals

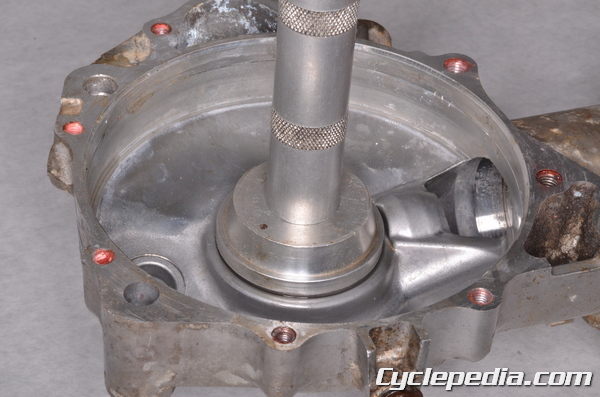

Special Tool – Bearing Driver Set: 57001-1129

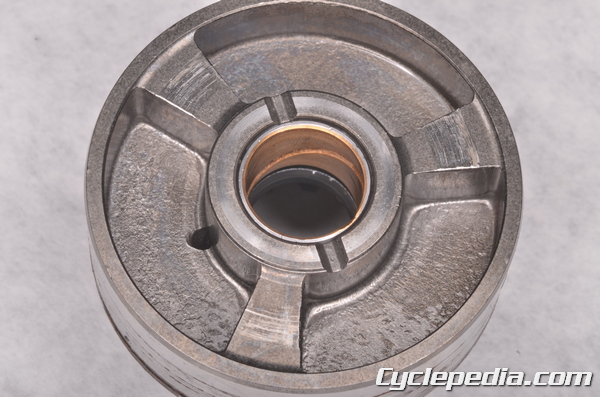

Inspect the coupling piece and shifter for wear and damage. There is an oil seal inside of the coupling piece. Replace the oil seal as needed. Drive in the new oil seal so that it sits 1 mm (0.04 in.) below the inside edge of the coupling piece.

Inspect the bushing in the coupling bushing piece. Measure the inside diameter of the bushing. Replace the coupling piece if the measurement exceeds the service limit or their are obvious signs of damage and wear.

Coupling Bushing: 13.000 – 13.018 mm (0.5118 – 0.5125 in.)

Service Limit: 13.048 mm (0.5137 in.)

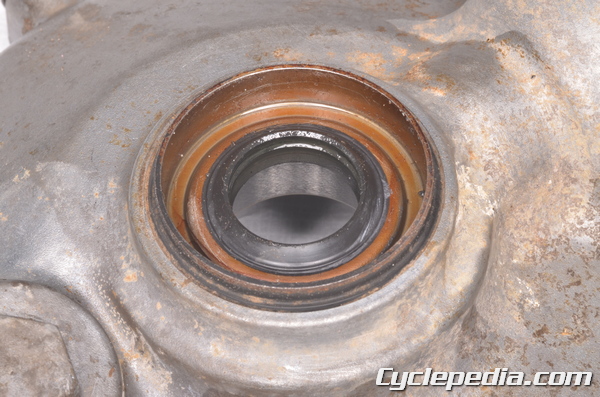

Inspect the differential case and cover oil seals for damage and deterioration. Remove the seals with a seal pick as needed.

When driving in the new oil seals use a suitable driver that is the same outside diameter as the seal.

Drive in the right differential case oil seal so that it is fully seated in its cavity.

Drive in the left differential cover oil seal so that it sits 4.6 – 5.6 mm below the surface of the cover.

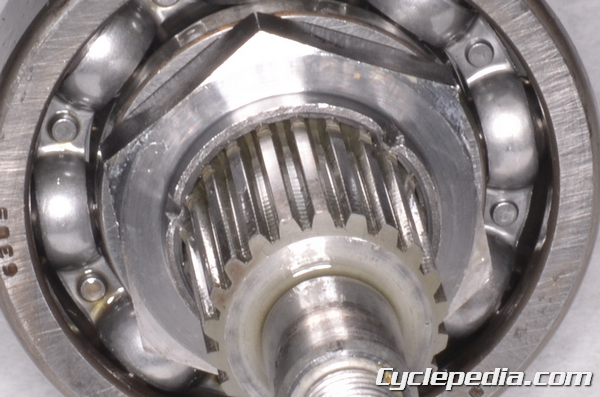

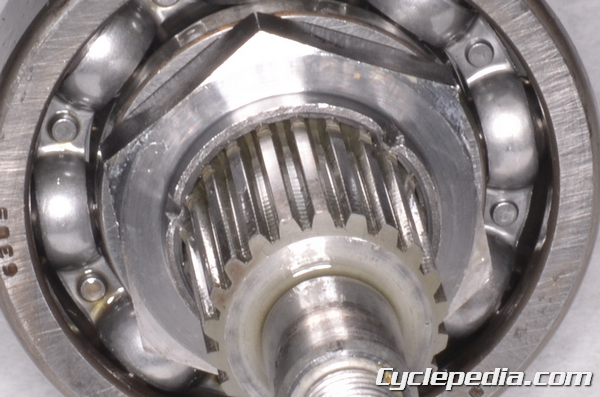

Inspect the right ring gear ball bearing by turning it with a finger. If the bearing is rough or has excessive play in the case it will need to be replaced.

Drive the ball bearing out of the right differential case from the outside.

Drive in the new bearing with a suitable driver that is the same outside diameter as the bearing. Make sure the bearing is fully seated in the case.

Inspect the left ring gear bearing and replace it as needed with a press.

Inspect the pinion bearing by turning it with a finger. If the bearing is rough or has excessive play in the case it will need to be replaced. To replace the pinion gear bearing first remove the snap ring with snap ring pliers. Remove the bearing with a suitable bearing puller. Drive in the new bearing and then install the new snap ring into the groove with snap ring pliers.

Inspect the pinion gear shaft bearing by turning it with a finger. If the bearing is rough it must be replace.

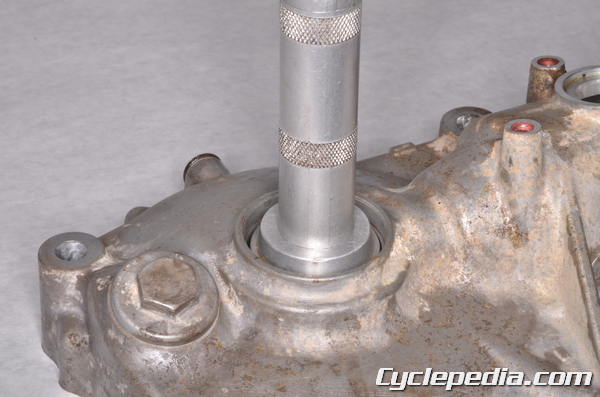

To remove the bearing from the pinion gear shaft first un-stake the nut with a small chisel.

Place the pinion gear shaft in the special holder tool and loosen the nut. Remove the nut and press the bearing off of the shaft.

Special Tool – Pinion Gear Holder m1.0: 57001-1485

Press the new bearing onto the shaft. Thread on the new nut so that the projection faces out. Place the pinion gear shaft in the special holder tool and tighten the nut to specification.

Pinion Gear Bearing Holder Nut: 127 N-m, 13 kgf-m, 94 ft-lb

Stake the nut projection in three places to lock it to the shaft.

Inspect the inner and outer needle bearings by feel and replace them as needed.

Clutch Pack

Measure the inner clutch disc thickness with a micrometer.

Measure the thickness of the clutch pack from the friction surface on one side to the other with a micrometer. Measure in sever locations. Avoid damaging the friction material.

Inner Disc Thickness | Clutch Pack Thickness

2.4 mm (0.0945 in.) | 16.7 – 17.3 mm (0.6675 – 0.6811 in.)

1.8 mm (0.0709 in.) | 16.31 – 17.9 mm (0.6875 – 0.7047 in.)

1.2 mm (0.0945 in.) | 17.91 – 18.5 mm (0.7051 – 0.7283 in.)

Select the correct inner clutch disc for assembly.

Like this Manual?

Like this Manual?