SAFETY FIRST: Protective gloves and eyewear are recommended at this point.

Remove the side covers. See the Side Covers topic for more information.

Make sure the idle speed is in specification while synchronizing the carburetors. See the Engine Idle Speed topic for more information.

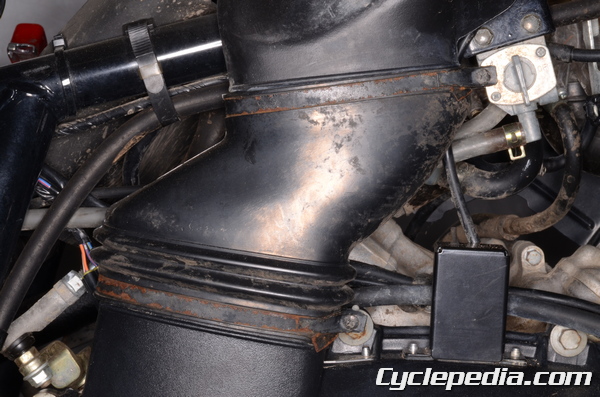

Loosen the air duct clamp screws with a #2 Phillips screwdriver.

Remove the air duct.

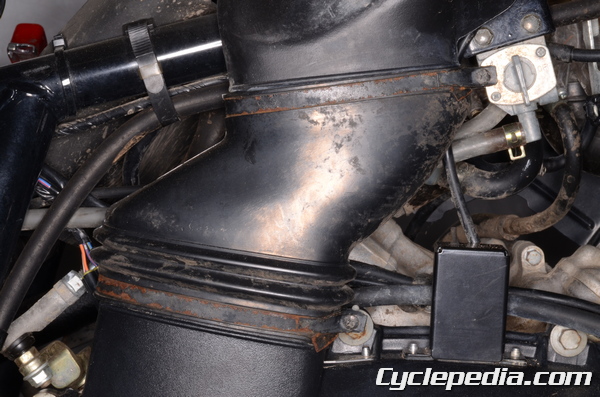

There is a capped vacuum fitting on each intake boot.

Remove the vacuum fitting caps.

Install a vacuum gauge onto the vacuum fittings, some gauges are different so be sure to follow the manufacturers instructions. Start the engine. At this point check your vacuum gauges if they are even then the carburetors are properly set.

If your gauges are uneven you will have to turn the butterfly valve synchronizing screw with a #2 Phillips to even out your reading. Make small adjustments and watch your gauges, you may have to turn the screw in or out. The readings from both carburetors should be within 2.7 kPa or 2 cmHg of each other.

If the carburetors cannot be synchronized to the requirements they may need to be cleaned.

Stop the engine

Remove the vacuum gauge and return the caps to the vacuum fittings.

Secure the caps with the clamps.

Install the air duct.

Tighten the air duct clamp screws securely with a #2 Phillips screwdriver.

Install the side covers. See the Side Covers topic for more information.

Like this Manual?

Like this Manual?