SAFETY FIRST: Protective gloves and eyewear are recommended at this point.

Inspection

Check that all tires are properly inflated at the same pressure. See the Tires topic for more information.

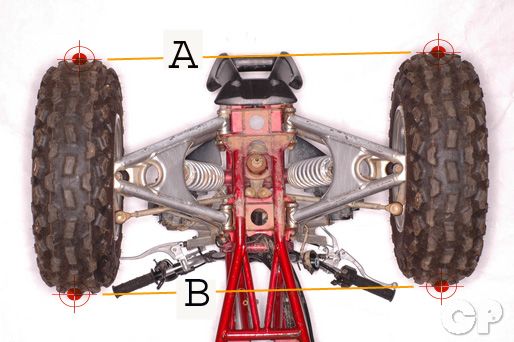

Straighten the front wheels on a level surface.

Measure the distances between the center of the tires with a toe-in-gauge on the front of the tires. Call this measurement A. Measure the distances between the center of the tires with a toe-in-gauge on the rear of the tires. Call the rear measurement B.

The difference between A and B is the toe-in measurement.

| Item | Standard |

| Wheel Alignment: Toe-in of front wheels |

0 ~ 20 mm (0 ~ 0.79 in.) at 1G |

Adjustment

Mark the tie-rods for reference.

Loosen the inner and outer tie-rod locknuts with a 14 mm wrench.

The outside lock nuts have reverse threads.

Turn the flats of the tie-rods with a wrench to change the distance between the tie-rod ends.

The Toe-in will be near the correct specification if the distance between the centers of the ball joints is set to specification. The amount of threads showing on each side of the tie rod should be even.

| Tie-Rod Length | 315 mm (12.4 in.) |

Turn the tie rods evenly until till the toe-in is within specification.

| Item | Standard |

| Wheel Alignment: Toe-in of front wheels |

0 ~ 20 mm (0 ~ 0.79 in.) at 1G |

Tighten the tie-rod locknuts to specification with a 14 mm wrench. Remember the outer locknuts have left hand threads.

| Fastener | Torque | ||

| N-m | kgf-m | ft-lb | |

| Tie-rod adjusting sleeve locknuts | 27 | 2.8 | 20 |

After adjusting the toe-in take the machine for a slow test ride. If the machine pulls to the left or right when the handlebar is facing straight ahead the toe-in needs to be readjusted more evenly to correct the problem.

Like this Manual?

Like this Manual?